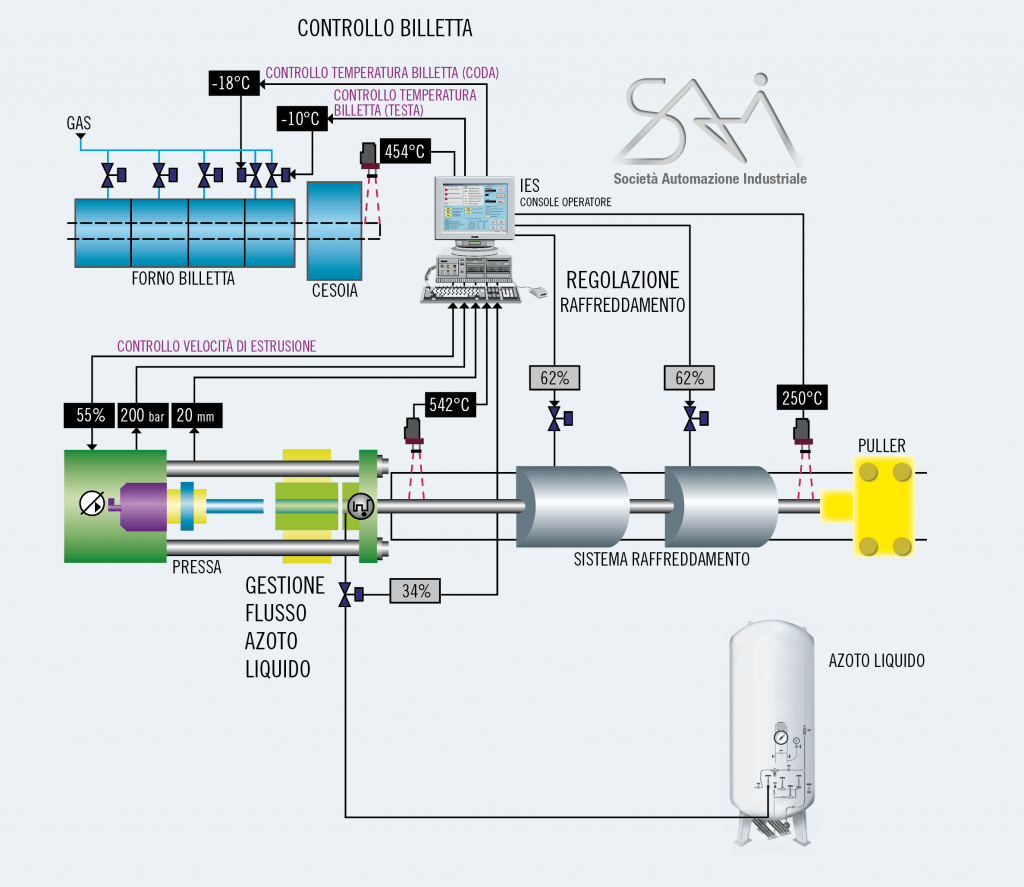

LIQUID NITROGEN MANAGEMENT

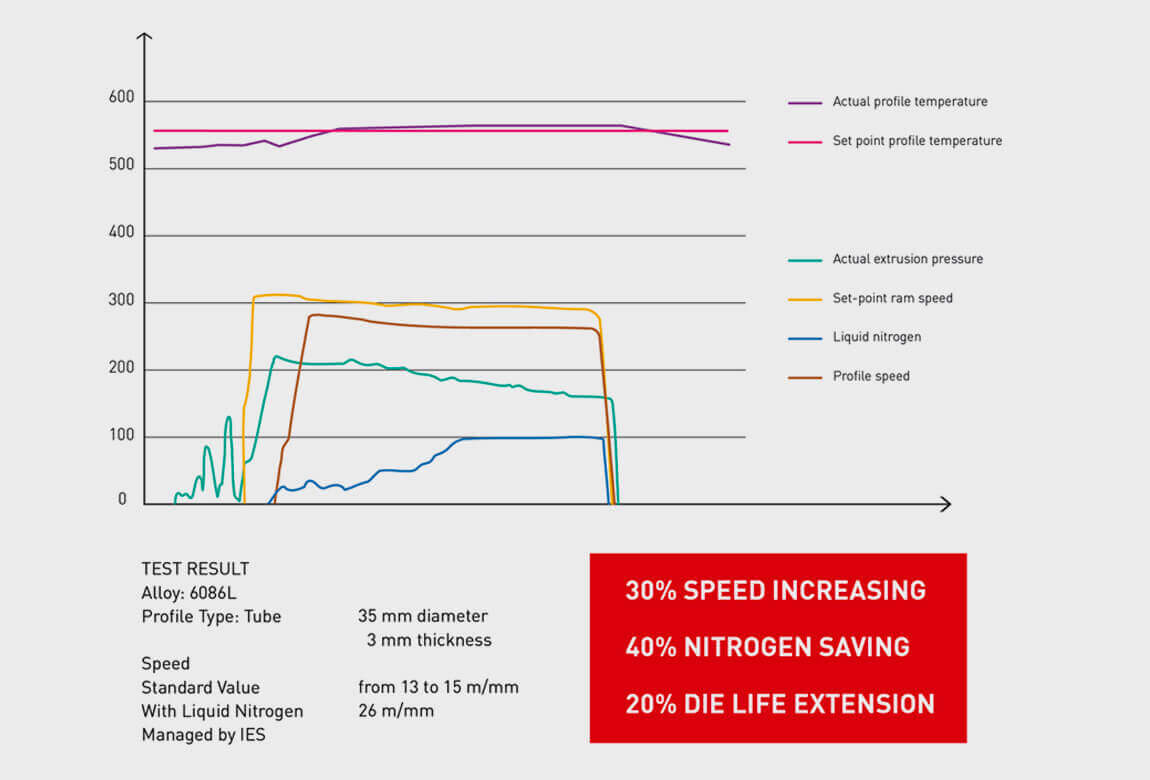

The function of Die Cooling managed with liquid nitrogen is a unique feature to improve extrusion performance. The liquid nitrogen flow controlled by the IES system gives important benefits:

- speed increasing by 30%

- significant saving of nitrogen compared to traditional regulation systems (about 40%)

- 20% die life extension

IES automatically regulates the amount of liquid nitrogen to be used depending on the production in progress and optimizes pressure, speed and temperature in continuous closed loop.