During extrusion the operator sets the ram speed. Speed may vary depending upon the pressure inside the cylinder and potential oil leakage from the hydraulic circuit, which will affect the profile speed and productivity.

Initial extrusion speed and productivity are reduced due to billet friction within the container.

At the end of extrusion, speed increases and outranges the set: profile temperature increases dramatically and it results in a substandard product.

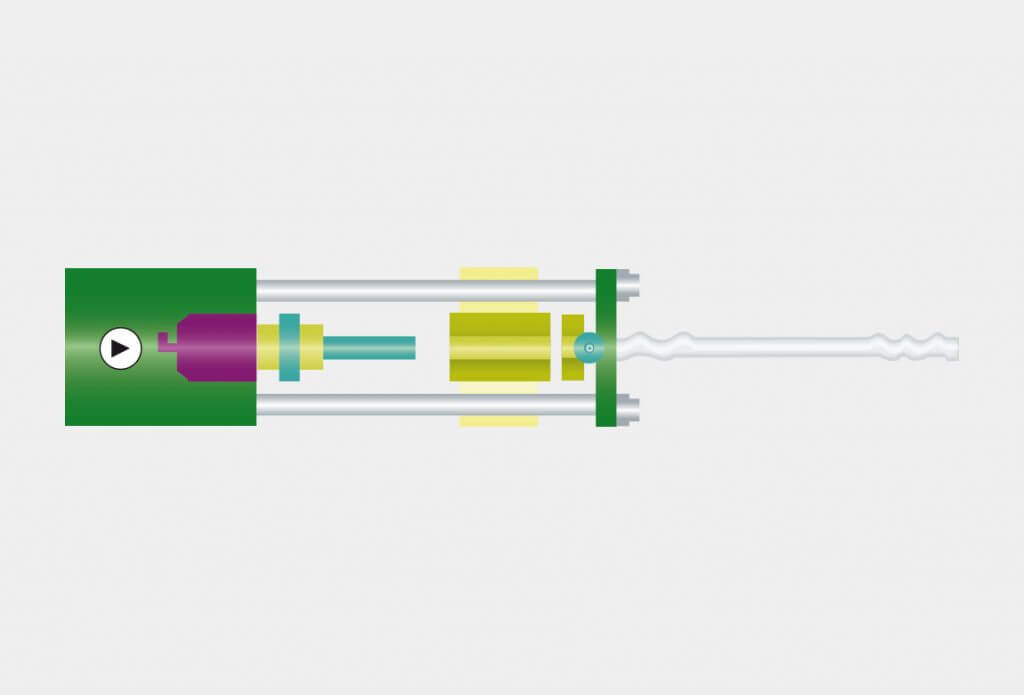

Isospeed automatically controls the oil feed to the cylinder ensuring constant speed during the extrusion process.

Isospeed can be easily integrated to all presses,including presses managed by a PLC or by relays.

No press stop required

Easy to integrate in existing plants

Speed may vary according to cylinder pressure and oil leakage from hydraulic circuit. These factors influence end profile speed, resulting in a low quality product